PVC Warning Tape: Applications, Role in Safety Marking, and Key Differences from Electrical Tape

In the intricate tapestry of industrial operations and safety protocols, few tools wield as much influence as PVC warning tape. This article embarks on an in – depth exploration of PVC tape, dissecting its diverse applications, the pivotal role of warning tape, and the nuanced distinctions between PVC tape and electrical tape. By illuminating these aspects, we aim to provide a comprehensive understanding of this essential safety and communication tool.

I. The Fundamentals of PVC Tape

PVC tape, short for polyvinyl chloride tape, is crafted from a resilient plastic material renowned for its durability, flexibility, and resistance to moisture and chemicals. This unique combination of properties endows PVC tape with an expansive range of applications across various industries. Available in a spectrum of colors, thicknesses, and adhesive strengths, PVC tape can be customized to meet specific requirements, making it a highly adaptable solution.

II. Diverse Applications of PVC Tape

2.1 Electrical Insulation

At the heart of electrical systems, PVC tape plays a vital role in insulation. By wrapping electrical wires and connections, it forms a protective barrier that safeguards against short circuits and electrical shocks, ensuring the safe and reliable operation of electrical installations.

2.2 Color – Coding Systems

In the bustling environments of warehouses, factories, and construction sites, PVC tape serves as an effective color – coding tool. Different colors are employed to denote various hazards, zones, or material types, streamlining operations and enhancing overall safety by providing clear visual cues.

2.3 Sealing and Bundling

For packaging and logistics, PVC tape’s robust adhesive properties make it ideal for sealing boxes and bundling items. This ensures that packages remain intact during transit, protecting the contents from damage.

2.4 Surface Protection

In the realms of construction and manufacturing, PVC tape acts as a shield for surfaces. Applied to floors, walls, and equipment, it prevents scratches, shields against dust, and safeguards against other contaminants, preserving the integrity and appearance of surfaces.

2.5 Warning and Hazard Marking

Among its many functions, PVC warning tape stands out as a crucial safety device. Specifically designed to alert individuals to potential hazards or restricted areas, it typically features bright colors and prominent warning messages or symbols to ensure maximum visibility.

III. The Crucial Role of Warning Tape

3.1 Hazard Identification

Warning tape, predominantly made from PVC, serves as a visual sentinel, marking hazardous areas such as construction zones, slippery floors, or regions with electrical risks. Its vivid hues and striking patterns immediately draw attention, compelling individuals to exercise caution.

3.2 Traffic Control

In outdoor settings, warning tape is an effective means of managing traffic flow. Whether redirecting pedestrians or vehicles, it can be strung up to create a clear and visible barrier, guiding movement away from danger zones.

3.3 Temporary Marking

During maintenance or repair work, warning tape provides a quick and efficient way to mark off unsafe areas. This temporary demarcation helps prevent accidents and keeps workers informed about their surroundings, ensuring a safer work environment.

3.4 Event Management

In the context of event planning, warning tape is used to define boundaries, separating VIP areas or restricted zones from public spaces. This helps maintain order and ensures that attendees are aware of where they can and cannot access.

3.5 Emergency Response

In times of crisis, warning tape is deployed rapidly to cordon off hazardous areas, such as chemical spills or unstable structures. Its immediate presence provides clear visual signals, facilitating a swift and coordinated emergency response.

IV. Distinguishing Between PVC Tape and Electrical Tape

Despite sharing a common base material, PVC tape and electrical tape have distinct characteristics and intended uses:

4.1 Material Composition

While both tapes are derived from PVC, electrical tape is formulated with specific properties to provide insulation and withstand high temperatures. It often features a greater thickness and a more tenacious adhesive, ensuring a secure bond with wires and electrical components.

4.2 Adhesive Characteristics

Electrical tape typically boasts a more aggressive adhesive, designed to adhere firmly to surfaces that may be exposed to heat and moisture. In contrast, PVC tape may have a less potent adhesive, making it suitable for general – purpose applications but less so for electrical work.

4.3 Color and Markings

Electrical tape is commonly available in a limited color palette, with black, red, and green being the most prevalent. These colors are used to signify different electrical functions. PVC warning tape, on the other hand, offers a wide array of colors and patterns, often emblazoned with bold warning messages or symbols for enhanced visibility.

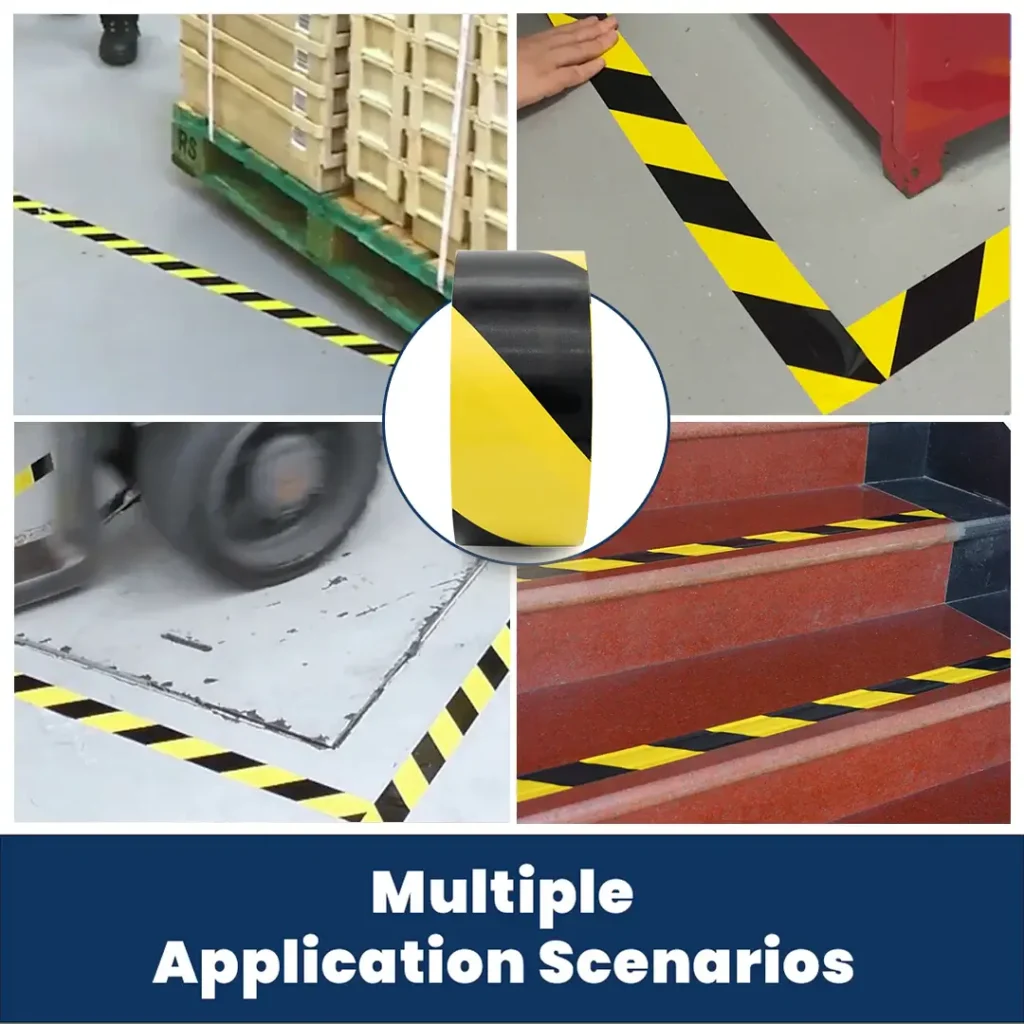

4.4 Application Scenarios

Electrical tape is primarily utilized for insulating electrical wires and connections, while PVC tape’s versatility allows it to be employed in a multitude of applications, including sealing, bundling, color – coding, and hazard marking.

V. Conclusion

PVC warning tape is an indispensable asset in industries where safety and effective communication are paramount. Its adaptability and functionality make it a go – to solution for a wide range of tasks, from hazard identification to electrical insulation. Recognizing the differences between PVC tape and electrical tape is essential for making informed decisions when selecting the appropriate product for specific applications. Whether in construction, event management, or electrical work, integrating PVC warning tape into safety procedures can significantly enhance awareness and mitigate the risk of accidents, ultimately contributing to a safer and more efficient work environment.