EVA vs PE Foam Tape: Key Differences, Uses & How to Choose the Right One

When selecting foam tape for your project, understanding the unique properties of EVA and PE foam tapes is essential. Each material offers unique benefits tailored to specific environments and applications This article breaks down their differences in flexibility, durability, and functionality to help you choose the right solution.

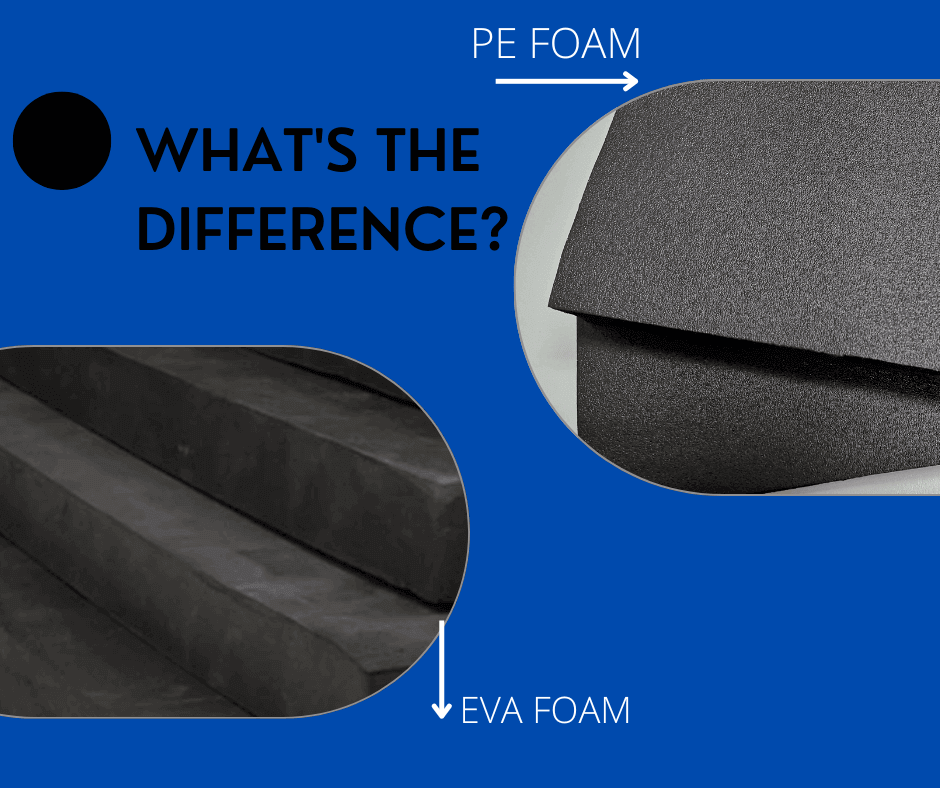

EVA Foam Tape: Flexibility and Outdoor Resilience

EVA (Ethylene-Vinyl Acetate) foam tape is prized for its adaptability and resistance to outdoor elements. Here’s what sets it apart:

- Key Properties:Exceptional Flexibility: Soft and compressible, ideal for cushioning, shock absorption, and conforming to irregular shapes.

- UV and Chemical Resistance: Withstands sunlight, moisture, and mild chemicals, making it suitable for outdoor applications like gaskets, window seals, or outdoor signage mounting.

- Adhesion: Strong bonding to smooth surfaces (metal, glass, plastic), ensuring reliable attachment in both indoor and outdoor settings.

- Common Uses:Cushioning in Electronics: Protects fragile devices during shipping.

- Weather Stripping: Seals gaps in doors/windows to prevent drafts.

- Outdoor Mounting: Secures panels, signs, or solar components in exposed environments.

PE Foam Tape: Strength and Moisture Resistance

PE (Polyethylene) foam tape excels in heavy-duty and moisture-prone scenarios. Its characteristics include:

- Key Properties:High Tensile Strength: Resists tearing and stretching, making it durable for industrial use.

- Moisture and Thermal Insulation: Blocks water penetration and maintains thermal stability, suitable for HVAC ducts, pipes, or cold storage.

- Surface Adaptability: Adheres well to rough or uneven surfaces (concrete, textured metal), providing versatility in challenging environments.

- Common Uses:Industrial Sealing: Bonds machinery components or seals joints in wet environments like bathrooms or basements.

- HVAC Systems: Insulates ducts to prevent condensation and energy loss.

- Heavy-Duty Mounting: Secures large fixtures or panels that require robust, long-lasting adhesion.

Side-by-Side Comparison: Core Differences

| Feature | EVA Foam Tape | PE Foam Tape |

| Flexibility | Highly flexible and compressible | Stiffer, with less give but more structural strength |

| Primary Strengths | UV resistance, outdoor durability | Moisture resistance, thermal insulation |

| Ideal Surfaces | Smooth, non-porous materials (metal, glass) | Rough, uneven, or textured surfaces |

| Typical Thickness | 1–5 mm (thin to medium cushioning) | 2–10 mm (thicker for heavy-duty insulation) |

| Adhesive Type | Strong on smooth surfaces | Versatile for rough or irregular textures |

| Weather Resistance | Excellent for UV and outdoor use | Superior in moisture-rich or humid environments |

Choosing the Right Tape for Your Needs

- Opt for EVA Foam Tape If:You need cushioning or shock absorption (e.g., packaging, electronics).

- The project involves outdoor exposure or requires UV resistance.

- The surface is smooth, and a flexible seal is needed.

- Opt for PE Foam Tape If:The application involves moisture, water, or thermal insulation (e.g., HVAC, plumbing).

- Heavy-duty strength or adhesion to rough surfaces is required.

- Durability in humid or industrial environments is a priority.

Conclusion

EVA and PE foam tapes serve distinct purposes, driven by their material properties. EVA shines in flexibility and outdoor resilience, while PE excels in strength and moisture control. By evaluating your project’s needs—whether it’s cushioning, sealing, insulation, or mounting—you can select the tape that ensures optimal performance. Understanding these differences empowers you to make an informed choice, ensuring your application is secure, durable, and fit for purpose.