Adhesive Tape- Exciting Packaging Tool

When it comes to adhesive tape, I’m sure we’re all no strangers. In daily life, tape can be considered a universal tool. When we deal with broken items, reinforced splicing or packaging heavy objects, tape can come in handy. Tape can be said to be one of the most common office supplies.

Adhesive tape is so common in our lives that it occupies almost every detail of our daily lives. Whether it’s at an offline hardware store or an online store, we can buy all kinds of adhesive tape at the drop of a hat. However, in the use of tape, I found a problem, why some tape use after tearing off, will leave a lot of sticky things, while some tape can be cleanly torn off; and why some tape can be firmly stuck to some objects, while other objects immediately “failure”?

Before answering these questions, let’s first understand the origins of the tape and the specific principles of it.

1.The past and present of adhesive tape

Tape, also called adhesive tape or tape paper, is a combination of a substrate and an adhesive. What is the substrate? We can think of it as a carrier for the tape, and the adhesive is what makes the tape sticky.

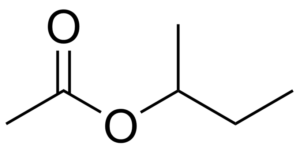

Early adhesives used in tapes were mainly natural rubber.But in modern times, various polymers are often used, usually acrylic adhesives, whose main component is sec-butyl acetate.The principle of adhesives being able to stick to objects is related to inter-molecular interactions. The molecules of the adhesive and the surface of other objects can form bonds between molecules, and this bonding can be the molecules firmly “tied”, so as to achieve the effect of adhesion.

The origin of adhesive tape dates back to 1928. There is an American named Richard Drew. He invented transparent cellophane tape, the first modern pressure sensitive tapes. Just a pressure can stick. And later adhesive will be coated in transparent plastic film, which invented the transparent tape!

The invention was a major asset during the Great Depression. It became a popular tool for repairing ripped, torn, or broken items rather than buying new ones. Books, window shades, toys, clothing, and even paper currency were mended with cellophane tape. Drew’s tape innovations were the first in a family of 900 pressure-sensitive tapes used worldwide in office, medical, electrical, construction, and other applications. Now 3M remains the leading manufacturer of pressure-sensitive tapes in the world.

2.How much do you know about common adhesive tapes?

Transparent Tape

The most common tape in life is the single-sided transparent tape, it is transparent PET, BOPP film as the substrate, coated with acrylic glue, and then divided into small rolls into the slitting.

Yellow tape

Usually when we buy online and receive express delivery, we often see yellow-colored tape, this tape is usually made of BOPP material.

There is basically no difference between yellow tape and transparent tape in use. Because the adhesive is yellow, the tape is yellow. And yellow tape is mainly used for sealing boxes, packaging fixing and other industries. The reason is that the color is more conspicuous, easy to identify. By the way, the color of the tape is determined by the color of the adhesive. Coloful adhesive makes tapes colorful. You can customized any colors you need, such as purple, blue, green and so on.

Double-sided tape

The use of double-sided tape is also very common. Double-sided tape is made by adding adhesive to a combination of paper, cloth and plastic film as the base material. According to the viscosity of the adhesive used, it can also be divided into oil-based double-sided adhesive, water-based double-sided adhesive, hot-melt adhesive tape, and reactive adhesive tape. Double-sided adhesive is double coated on BOPP film, and then the release agent is applied to both sides of the adhesive paper to prevent adhesive from adhering. For special use environments, double-sided adhesive is more convenient to use than transparent adhesive.

Electrical tape

Electrical tape, as the name suggests, is the tape used by electricians. Its most important feature is insulation, and it is often used to wrap pipes and wires. There are two main types of electrical tape, PVC and vinyl. In addition to being a good insulator, electrical tape also has a long-lasting adhesive, as well as good resistance to high temperatures and high voltages.

Overall, different tapes have their own purposes, according to the different use of the scene, we can flexibly adopt different tapes with the use.

Going back to what was mentioned at the beginning, the stickiness or otherwise of the tape after use to tear it off often depends on the material it is made of and the length of time it has been in use. So how can we deal with the situation where the tape leaves traces of stickiness after use?

I recommend using a high concentration (75% or more) of alcohol. Alcohol is composed of ethanol, which is a common organic solvent that can dissolve away most of the adhesive. In addition, windex also contains a high organic solvent content, can also be used to clean up the marks left by the tape, the effect is very good.

After reading the above, do you know more about adhesive tape? https://wandepackaging.en.alibaba.com/productlist.html?spm=a2700.shop_index.88.14.cd8e2524LtsPVu