Classifications of Stretch Film

Stretch film is also known as winding film and wrapping film. Its base material is LLDPE, which is generally made by adding additives with adhesive properties, such as PIB masterbatch, to PE film material. It is processed by casting process and is a linear low density polyethylene. The surface of the stretch film has micro-adhesive. It can stick to each other. Stretch film of different sizes, specifications and colors has different uses. Let’s take a look at the professional analysis about the classification, characteristics and application range of stretch film.

Features of stretch film

1, strong fastening: good anti-tear performance and anti-puncture, which can effectively prevent items from being stolen and transported off.

2, good toughness: horizontal and vertical have good tear resistance and extensibility, good resilience. So it can pack any shape of items into a whole with high efficiency.

3, environmental protection and beautiful: stretch film is recyclable material, odourless and non-toxic can be directly on the food packaging. Good transparency, both hygienic and beautiful.

4, low cost: the use of stretch film cost is very low, and packing an item of the required amount is not high, greatly saving resources.

5, convenient and quick: the use of stretch film is very simple, reducing the work intensity of workers. And its specifications can also be customized according to the demand for slitting.

6, safety: in the packing operation, do not have to worry about high temperature machines and other hidden dangers, greatly strengthening the security of the warehouse.

Classification of Stretch Film

Stretch film can be classified by its own colour, which can be divided into: transparent, black, coloured.

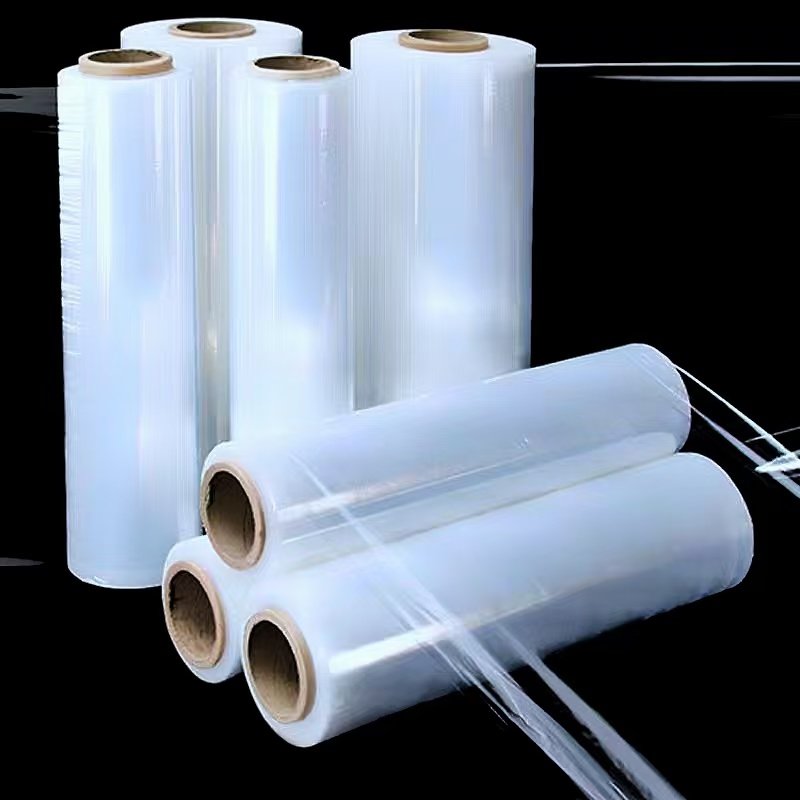

1、Transparent stretch film

Transparent stretch film has a good surface gloss, close to transparent. When we use transparent stretch film to package items, we can still see the goods clearly. Many supermarkets use this colour to package food, ensuring hygiene and improving visibility at the same time. Transparent stretch film is also used by many companies to package and display samples. After packaging, the items inside can still be seen through the film, providing protection against dust, moisture and friction. https://baijiahao.baidu.com/s?id=1749004415401296989

2、Black Stretch Film

Black stretch film can not be seen through the film inside the goods. This kind of stretch film is mainly used to pack more important items, isolate the role of the visual can play a very good anti-theft and anti-prying role.

3、Colored stretch film

Colour stretch film in a variety of colors, the purpose of use also varies from person to person. A small number of buyers are worried about the colour stretch film with toxic chemical dyes and do not dare to use. In fact, not, colour stretch film is added in the production process of masterbatch, belong to the non-toxic and tasteless safety products, so you can rest assured that the use.

Classification by Specification

1、mini stretch film

The weight of a single roll of mini stretch film is generally 0.3~1kg, and this kind of small-size stretch film is suitable for packing smaller items, such as some small parts and accessories.

2、Hand stretch film

Hand stretch film is generally 1.5~4kg, this specification can be used to pack large and medium-sized items, can also play a fixed role.

3、Machine stretch film

Most of the machine stretch film is more than 10kg. This kind of specification is operated by machine, used for packing and fixing large goods.

The above is the classification of stretch film by colour and specification. I believe you have a better understanding of stretch film. You can refer to these classifications in the process of use, and choose the suitable stretch film according to the demand.

Classification according to other methods

1, according to the packaging method, stretch film packaging can be divided into: manual stretch packaging, damping stretch packaging, pre-stretch packaging.

2, according to the material classification, stretch film can be divided into polyethylene stretch film, polyvinyl chloride stretch film, ethylene – vinyl acetate stretch film and so on. At present, a large number of production and use of stretch film, are based on linear polyethylene as the basic raw material. Polyethylene stretch film has become the mainstream of stretch film.

3, according to the structure of the film, stretch film can be divided into single-layer stretch film and multi-layer stretch film. Generally speaking, only one side with viscosity is often referred to as single-side sticky stretch film. With the improvement of film production equipment and technology, the advantages of multi-layer stretch film are more and more prominent. This is conducive to improving product quality and reducing product costs. At present, the single-layer structure of the stretch film has gradually reduced the trend.

4, according to the different moulding process, stretch film can be divided into blown stretch film and cast stretch film. Cast stretch film performances better.

5, according to the use of classification, stretch film can be divided into industrial packaging stretch film (such as home appliances, machinery, chemicals, building materials, etc.), agricultural packaging stretch film and home packaging stretch film. https://wandepackage.com/sorting-of-stretch-film/