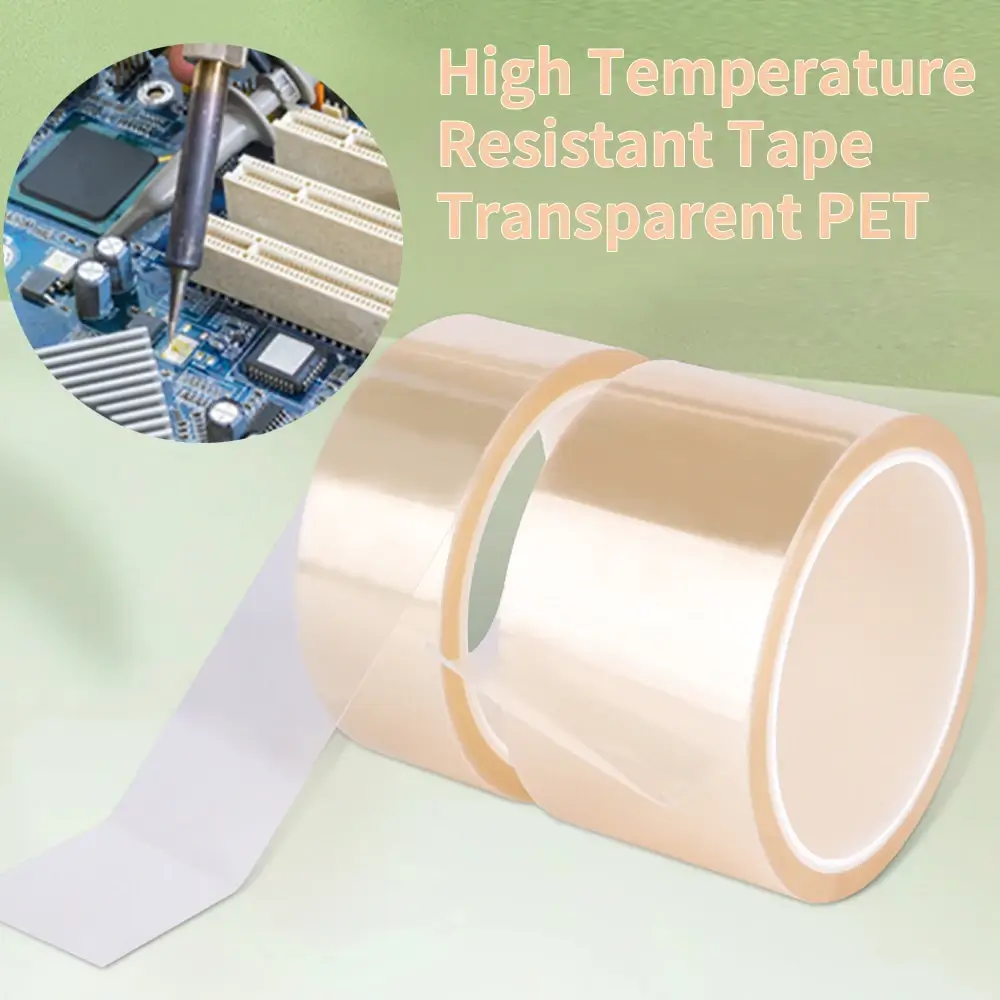

PET High Temperature Tape Protective Film: Applications in Electronics, Metal Coating & Automotive Industries

PET high temperature tape protective film, often simply referred to as tape protective film, is a specialized adhesive product designed to withstand extreme environments while providing reliable surface protection. While some applications have shifted to high-performance material films, PET high temperature tape protective film retains unique advantages in niche industries due to its heat resistance and versatility.

Core Composition and Properties

This film consists of a polyethylene terephthalate (PET) substrate coated with acrylic adhesive on both sides, offering a balance of durability and flexibility. Key characteristics include:

- Color: Predominantly transparent or black, allowing visibility or light-blocking as needed.

- Thickness: Ranges from 0.05mm to 0.2mm, catering to lightweight or heavy-duty applications.

- Temperature Resistance:Long-term: Long-term heat resistance: 120–150°C; Short-term peak resistance: 200–220°C.

-

- Short-term: Endures up to 140–200°C, making it suitable for high-temperature processes.

- Stability: Excellent dimensional, thermal, and chemical resistance (e.g., solvents, acids).

- Adhesion: Strong initial tack and reliable peel adhesion on plastics, metals, and rubbers, with easy die-cutting for custom shapes.

Unique Applications of PET High Temperature Tape Protective Film

The film’s heat resistance and shielding capabilities make it indispensable in industries requiring extreme-temperature protection:

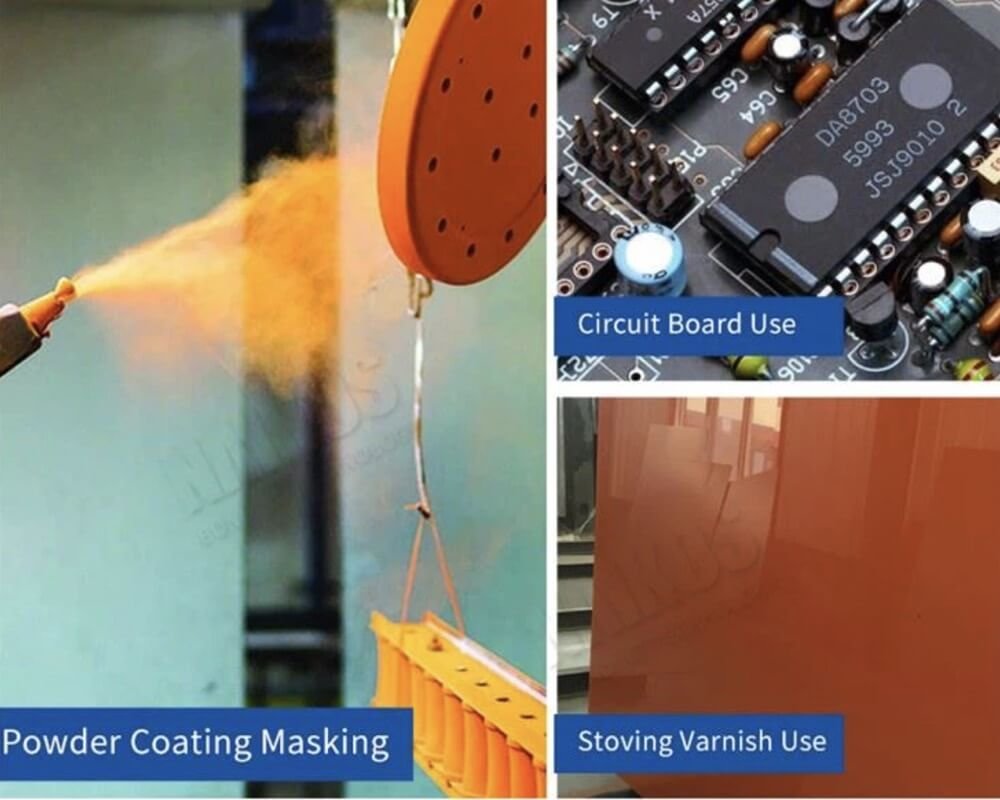

- Metal & Powder Coating Industries

- Surface Protection: Shields uncoated metal surfaces (e.g., computer cases, cabinets) during powder coating, electroplating, or electrophoresis to prevent overspray or chemical damage.

- Masking: Provides precise edge masking for uniform coating application, ensuring clean, professional finishes.

- Electronics & PCB Manufacturing

- PCB Processing: Secures components (resistors, capacitors) during assembly and shields gold fingers from immersion in electroplating solutions or soldering fluxes.

- Insulation & Shielding: Acts as a thermal barrier for electronic components during high-temperature soldering or reflow processes.

- Automotive & Industrial Coatings

- Painting & Coating: Protects automotive parts, machinery, or equipment during spray painting, powder coating, or oven curing, resisting heat and chemical solvents.

- Component Fixing: Bonds and stabilizes parts temporarily during manufacturing, ensuring alignment without residue upon removal.

- Home Appliance & Machinery Production

- High-Temperature Binding: Secures parts in appliances (e.g., ovens, heaters) or industrial machinery during coating processes, maintaining structural integrity under heat.

- Mold Release & Industrial Sealing

- Mold Joints: Used as a release agent in composite molding or casting to prevent adhesion between molds and materials, facilitating easy demolding.

Advantages Over Alternative Films

| Feature | PET High Temperature Tape Protective Film | Standard Protective Films |

| Temperature Tolerance |

120–150°C long-term, 200–220°C short-term |

Limited to 60–80°C for standard films |

| Chemical Resistance | Resists solvents, plating chemicals | Prone to degradation in harsh environments |

| Adhesion Strength | Strong acrylic adhesive for rugged surfaces | Weaker adhesion on low-energy surfaces |

| Application Flexibility | Suitable for complex, curved, or uneven surfaces | Best for flat, smooth surfaces |

Key Considerations for Use

- Surface Preparation: Ensure surfaces are clean, dry, and free of oils to maximize adhesion.

- Temperature Matching: Always verify the film’s temperature rating against the process requirements to avoid failure.

- Release Force: For sensitive applications (e.g., delicate electronics), test peel strength to ensure residue-free removal.

- Custom Fabrication: Leverage die-cutting capabilities to create tailored shapes for unique components or irregular surfaces.

Conclusion

PET high temperature tape protective film remains a critical tool in industries where extreme heat, chemical exposure, and precise masking are non-negotiable. From electronics manufacturing to automotive coating lines, its ability to provide reliable, high-temperature protection without compromising surface integrity sets it apart. As technology continues to demand robust solutions for harsh environments, this film will remain an essential component in ensuring product quality and process efficiency. Whether shielding metal during powder coating or securing PCBs during soldering, PET high temperature tape protective film delivers performance where standard films fall short.