Wande Packing Masking Tape: High-Temperature Options, Applications for Painting & Industrial Use

Masking tape, a cornerstone in temporary adhesion solutions, is a pressure-sensitive tape crafted from thin, tear-resistant paper coated with a specialized adhesive. Designed for easy application and residue-free removal, it is an essential tool in countless projects. Among industry leaders, Wande Packing stands out for its innovative masking tape formulations, including standard and high-temperature variants, engineered to meet diverse operational needs.

I. Understanding Wande Packing’s Masking Tape: Core Features

Wande Packing’s masking tape is defined by its precision adhesive technology and quality materials. The brand’s commitment to excellence is evident in:

- Clean Removal: Formulated to leave no sticky residue on surfaces, ideal for delicate applications like painting, crafting, or electronics assembly.

- Surface Compatibility: Bonds effectively with wood, metal, plastic, and glass, while adapting to both smooth and slightly textured substrates.

- Customization: Available in various widths, colors, and adhesion strengths, including specialty tapes for high-temperature environments.

II. Temperature Resistance: Standard vs. High-Temperature Masking Tape by Wande

2.1 Standard Masking Tape

Wande’s standard masking tape is optimized for everyday use, with temperature resistance up to 200°F (93°C) for short durations. This makes it suitable for:

- Home painting projects

- Crafting and DIY tasks

- Temporary labeling and surface protection

Note: Prolonged exposure to temperatures above 200°F may cause adhesive softening or residue transfer.

2.2 High-Temperature Masking Tape

For industrial applications requiring heat tolerance, Wande Packing offers high-temperature masking tape capable of withstanding 300°F (149°C) and beyond. Key features include:

- Heat-Resistant Adhesive: Formulated with silicone or ceramic-based compounds to maintain integrity during automotive painting, powder coating, or oven curing processes.

- ** Reinforced Backing**: Synthetic paper or fiberglass-reinforced materials prevent tape degradation in extreme heat.

- Industrial Certifications: Meets standards for aerospace, automotive, and manufacturing environments, ensuring reliability in critical workflows.

III. Diverse Applications of Wande Packing’s Masking Tape

3.1 Painting and Coatings

- Professional Finishes: Wande’s masking tape creates sharp, clean lines in residential, commercial, and automotive painting. The high-temperature variant is ideal for factory-scale paint processes, where oven curing at 250°F is common.

- Example: In a recent automotive project, Wande’s high-temperature tape was used to mask trim pieces during a 280°F powder coating cycle, ensuring no adhesive bleed or surface damage.

3.2 Arts, Crafts, and DIY

- Creative Freedom: Available in decorative patterns and colors, Wande’s standard masking tape is a favorite for:Stenciling on furniture or walls

- Scrapbooking and paper crafts

- Temporary hold for decals or embellishments

- User Feedback: Crafters praise the tape’s easy tearability and residue-free removal, even on delicate paper or fabric.

3.3 Industrial and Electronics

- Automotive Assembly: Wande’s high-temperature tape is used in car manufacturing to protect components during engine bay painting or underbody coating.

- Electronics Production: Standard masking tape secures wires, labels circuit boards, or protects LCD screens during soldering (temperatures up to 180°F).

3.4 Home Improvement and Labeling

- Renovation Projects: Marks measurement lines, protects fixtures from paint splatter, or holds drop cloths in place.

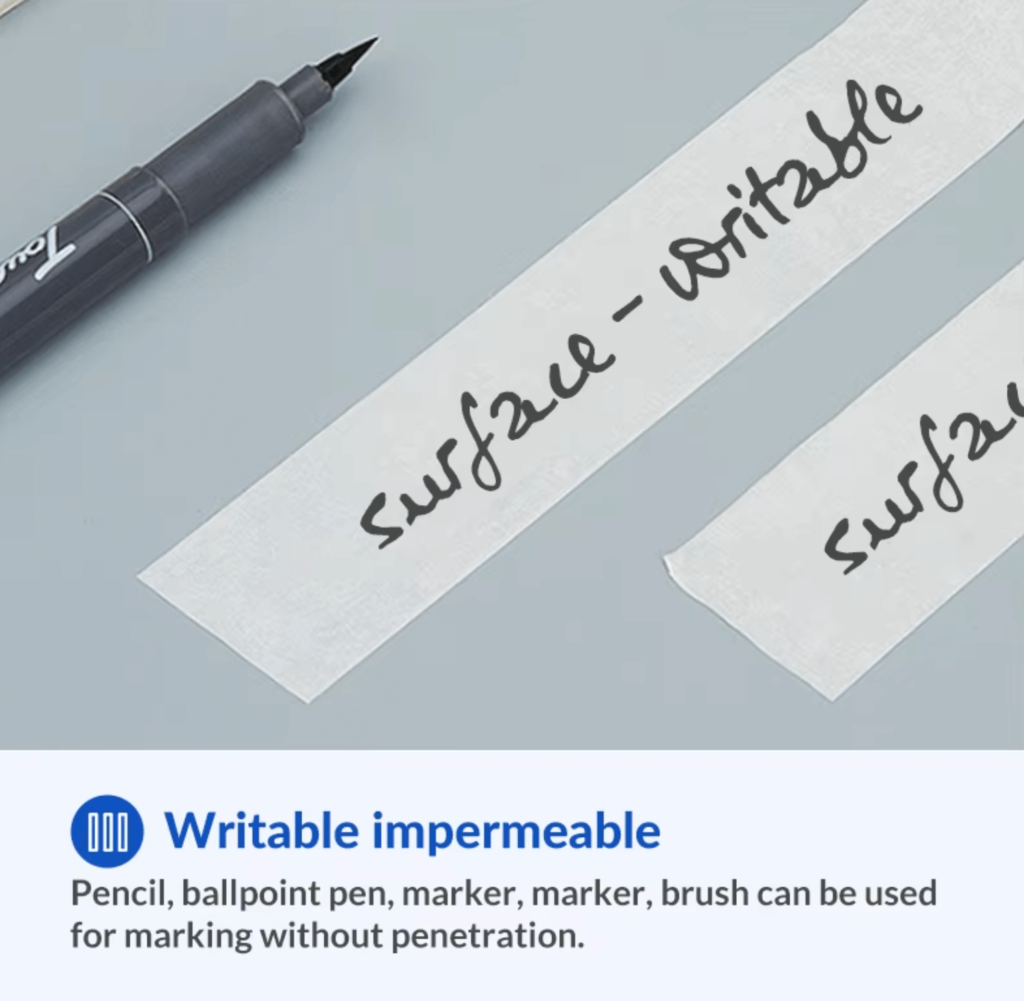

- Organizational Solutions: Writable surface allows quick labeling of boxes, storage bins, or files in offices and warehouses.

IV. Best Practices for Using Wande Packing’s Masking Tape

4.1 Surface Preparation

- Clean the target surface with isopropyl alcohol to remove dust, oil, or wax.

- For rough surfaces (e.g., unfinished wood), apply light pressure to ensure adhesive contact.

4.2 Application Techniques

- Sealing Edges: Run a finger or tool along the tape’s edge to create a tight seal, preventing paint or moisture from seeping underneath.

- Curved Surfaces: Stretch the tape slightly (without deforming it) to conform to curves, such as around pipes or moldings.

4.3 Removal Guidelines

- Timing: Remove standard masking tape within 24–48 hours of application for optimal clean removal. High-temperature tape can stay in place longer but should be peeled off while the surface is still warm (not hot).

- Angle and Speed: Peel slowly at a 45° angle, pulling the tape back on itself to reduce stress on the surface.

4.4 Product Selection Guide

| Application | Recommended Wande Tape | Temperature Rating | Key Benefit |

| Home painting, crafts | Standard Masking Tape | Up to 200°F (93°C) | Easy tear, colorful options |

| Automotive painting, powder coating | High-Temperature Masking Tape | Up to 300°F (149°C) | Heat resistance, industrial-grade |

| Electronics assembly | Low-Profile Masking Tape | Up to 180°F (82°C) | Thin profile, non-conductive |

V. Why Choose Wande Packing?

- Quality Assurance: All tapes undergo rigorous testing for adhesion, temperature resistance, and residue performance.

- Custom Solutions: Tailored tape widths, adhesives, and packaging options for bulk orders or specialized projects.

- Sustainability: Commitment to eco-friendly materials, including recyclable paper backing in select products.

VI. Conclusion

Wande Packing’s masking tape combines precision, durability, and versatility, making it an indispensable tool for professionals and DIY enthusiasts alike. Whether you need a reliable tape for home painting, industrial heat applications, or creative crafts, Wande’s range ensures optimal performance. By following best practices for application and removal, users can leverage these tapes to achieve clean, professional results every time.